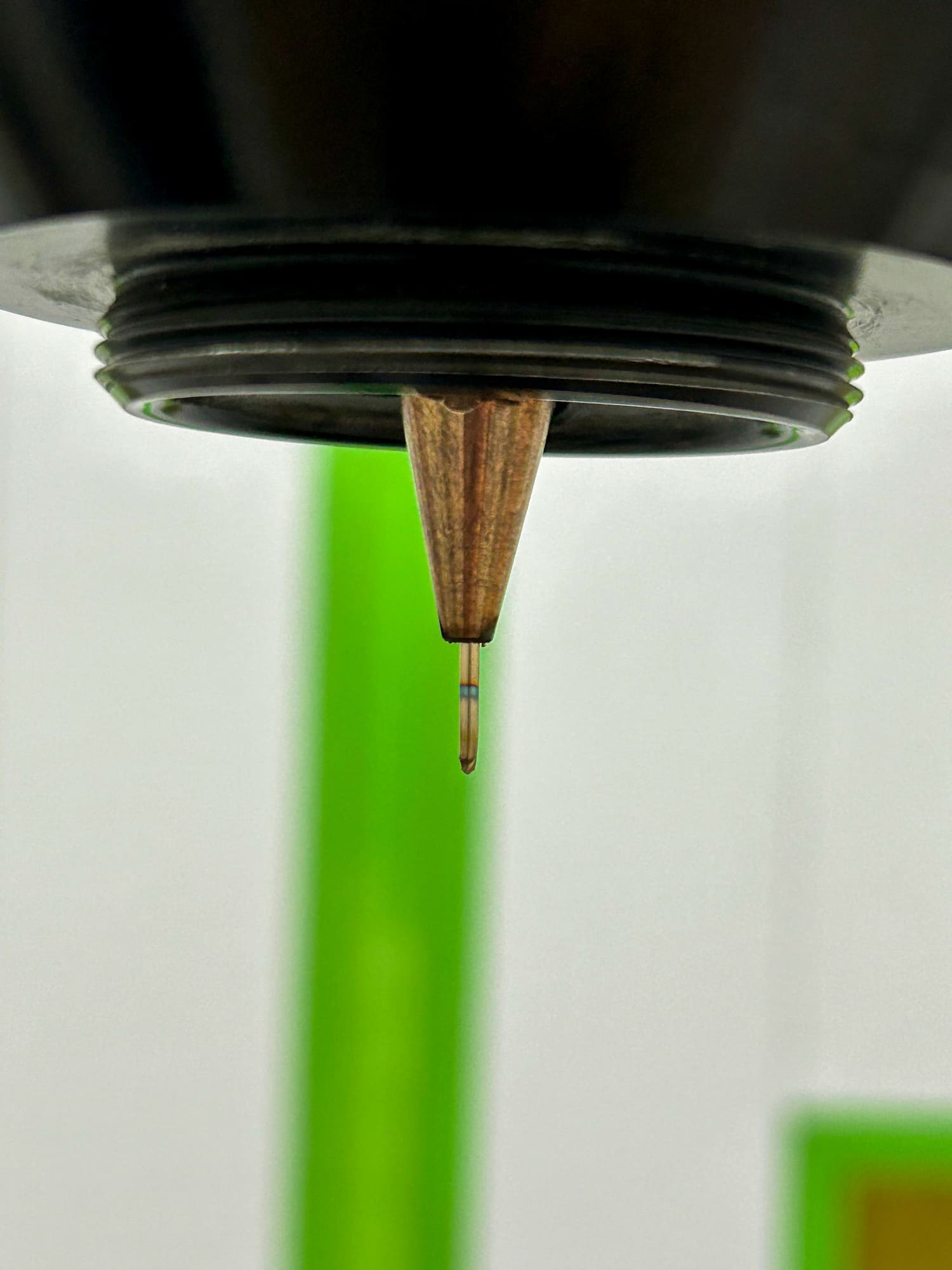

At our foundry, we have taken a step that redefines the limits of contemporary casting. Through a pioneering R&D project, we have managed to incorporate 3D metal printing, a technology that fuses art, innovation, and precision in a way that has never been seen before.

Thanks to this new technique, we have become the first artistic foundry in the world capable of producing titanium sculptures using a layer-by-layer casting process, without relying on molds.

This breakthrough opens up new horizons for contemporary sculpture, where technology and tradition combine to create works with a level of detail, durability, and purity that would be impossible to achieve using traditional methods.

Adhyart technology, innovation born from art

The name Adhyart defines this exclusive technology developed by Capa Esculturas. It represents the union between art and technology that is driving the revolution in contemporary sculpture.

Unlike lost wax casting, where the sculpture requires a model, mold, casting, and subsequent welding, sanding, and patination, Adhyart prints the metal directly layer by layer using selective melting. This system allows for much greater precision and unprecedented structural homogeneity, opening up new possibilities in the creation of shapes and volumes that are impossible with conventional methods.

Among the metals we currently work with, we can highlight bronze, stainless steel, titanium, nickel (alloy 718 or Inconel), and white bronze, among others. The result is sculptures without pores, with an impeccable finish and a completely uniform internal structure, which represents a technical and aesthetic revolution in the world of artistic casting.

The metals of the future: titanium, nickel, and stainless steel

Each metal offers unique properties that expand the possibilities of sculptural art.

- Titanium stands out for its extreme strength, structural lightness, and pure metallic finish, with warm reflections and unmatched durability.

- Nickel, especially in its Inconel 718 alloy, provides exceptional resistance to temperature and corrosion, ideal for sculptures that require stability and precision.

- On the other hand, stainless steel offers a shine and strength that make it one of the most versatile materials for both interior and exterior construction projects.

A technical revolution: speed, precision, and cost reduction

Adhyart technology not only transforms the creative process, but also the technical and economic efficiency of casting.

The 3D metal printing system can drastically reduce production times, as it eliminates intermediate stages and allows complete control from design to finish. Whereas parts used to require weeks of manual labor to create, and further weeks to finish, they can now be produced in a matter of days.

In addition, sculptures created using the Adhyart system are much easier to weld, as complex sections can be joined together that would be difficult or even impossible to assemble using traditional casting methods.

This technical improvement also translates into a logical reduction in costs, as the system requires less material, less specialized labor in intermediate stages, and above all, greater precision from the start of the process, minimizing errors and material waste.

How Adhyart is transforming artistic casting

Since its inception, Capa Esculturas has maintained a balance between traditional craftsmanship and technical innovation. With the arrival of the Adhyart system, our workshop has become a space where artistic casting evolves toward the future without losing its essence.

This new technology does not replace lost wax casting, but rather complements it, offering artists a modern alternative that expands their creative possibilities. This digital process allows for prototyping, adjusting, and producing unique or serial works with millimeter-level detail.

The result is sculptures that combine the artisanal soul of classic casting with the precision of digital modeling, a commitment to sustainability by reducing material waste and cutting down on time, marking a clear before and after in contemporary sculpture worldwide.

A pioneering achievement in the world

Being the first artistic foundry in the world to master 3D printing with different metals is a milestone that consolidates Capa Esculturas as an international benchmark in sculptural innovation.

Until now, this type of technology only existed in highly engineered industrial environments. However, thanks to Adhyart, Spanish artistic casting is now at the forefront of global innovation, offering artists and creators a revolutionary tool to bring their ideas to life.

This innovation represents a commitment to sustainability, resource efficiency, and artistic excellence, values that have always defined the work of Capa Esculturas.

Some materials such as titanium, nickel, bronze, among others, are no longer reserved for industry and have become a new form of artistic expression. With Adhyart, Capa Esculturas opens the door to an era in which each cast layer reflects the perfect union between art, science, and technology.

Each work created with this system not only demonstrates innovation, but also a clear vision of the future: that art does not stand still, it evolves. And in that evolution, Capa Esculturas leads the way. You can view our completed projects or contact us to bring your idea to life with 3D metal printing.